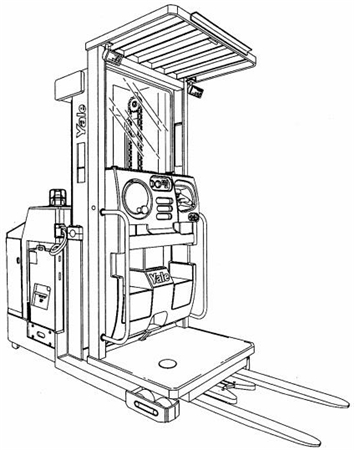

This is the COMPLETE Service Repair Manual for the Yale OS030BC, SS030BC Order Selector. It contains deep information about maintaining, assembly, disassembly and servicing your Yale OS030BC, SS030BC Order Selector.

This Manual contains information and data to this model. has specs, diagrams, and actual real photo illustrations, and schemes, which give you complete step by step operations on repair, Diagnosing, servicing, technical maintenance & troubleshooting procedures for your machine. this manual offers full information you need for repair your machine. the information in this manual will enable you to find trouble and to understand how to repair and maintain your machine without going into service. YOU CAN DO THE REPAIRS YOURSELF AND SAVE MONEY $$$

SERVICE REPAIR MANUAL CONTAINS:

=========

1 OPERATING INSTRUCTIONS

MODEL DESCRIPTION

OPERATING CONTROLS

SAFETYAND INFORMATIONAL LABELS

NAMEPLATE

SERIAL NUMBER

MODEL CODE

TRUCK WEIGHT

CAPACITY RATING

SAFETY LABELS

OPERATING PROCEDURES

OPERATOR PRE-CHECKSAND INSPECTION

OPERATOR’S DAILY CHECK LIST

OPERATING PRECAUTIONS

2 GENERAL TRUCK AND LUBRICATION SCHEDULE

MAINTENANCE

SAFE MAINTENANCE PROCEDURES

BATTERY OPERATION

BATTERY INSTALLATION

WATER ADDITIONS

CLEANING

CHARGING THE BATTERY

CHANGING THE BATTERY

FORKS

TETHER LINEAND BELT

PALLET CLAMP

HOW TO PUTA LIFT TRUCK ON BLOCKS

HOW TO RAISE THE DRIVE/ STEER TIRE

HOW TO RAISE THE LOAD WHEELS .

LUBRICATION INSTRUCTIONS

EVERY8 HOURS

EVERY350 HOURS

EVERY2000 HOURS

YALE WARRANTY INFORMATION

RECOMMENDED SCHEDULES OFMAINTENANCE

HYDRAULIC OILS

GEAR OILS

GREASE

ANTI-SEIZE LUBRICATING COMPOUND

TIRES AND WHEELS

HOW TO CHANGE THE DRIVE/STEER TIRE

HOW TO CHANGE THE LOAD WHEELS

HOW TO MOVEA DISABLED LIFT TRUCK

HOW TO TOW THE LIFT TRUCK

PRECAUTIONS FOR TRUCKS IN STORAGE

PRECAUTIONS FOR BATTERIES IN STORAGE

FASTENERS

INTRODUCTION

THREADS, NOMENCLATURE

STRENGTH IDENTIFICATION

3 ELECTRICAL SYSTEM

INTRODUCTION

GENERAL

COMPONENT REPAIR AND TESTING

GENERAL

MAININTERFACE BOARD (MIB)

DESCRIPTION/FEATURES

OPERATION

PRIORITIES

REMOVAL

REPAIR

INSTALLATION

CHECKING THE MODEL CODEAND SET-UP STATUS

CHECKING THE MIB SOFTWARE VERSION

DEFAULT VALUES

CUSTOM PROGRAMMING

MAIN INTERFACE BOARD ADJUSTMENTS

GENERAL

MIB SET-UP SEQUENCE

STEP 1 ENTERING THE SET-UP MODE

STEP 2 ERASEAND RETURN TO FACTORY DEFAULT VALUES .

STEP 3 HYDRAULIC POTENTIOMETER SET-UP

STEP 3B SETTING FUNCTIONS 02, 04 AND 05

STEP 4 EXITING THE SET-UP MODE

STEP 5 ADJUSTING MAXIMUM LOWERING RATE

BELOW24 INCHES

CHANGING THE MIB VALUES

INCREASING/DECREASING THE FUNCTION NUMBER

INCREASING/DECREASING THE FUNCTION VALUE

MIB SET-UP PROCEDURE

STEP 1 ENTERING THE SET-UP MODE

STEP 2 ERASEAND RETURN TO FACTORY DEFAULT VALUES .

STEP 3 HYDRAULIC POTENTIOMETER SET-UP

STEP 3B SETTING FUNCTIONS 02, 04 AND 05

STEP 4 EXITING THE SET-UP MODE

EXIT WITHOUT SAVING NEW VALUES

EXITAND SAVE NEW VALUES

STEP 5 ADJUSTING THE MAXIMUMLOWERING RATE

BELOW24 INCHES

MIB FUNCTION DESCRIPTIONS

MIB CODES

MIB STATUS CODES

MIB WARNING CODES .

MIB FAULT CODES

STATUS, WARNING AND FAULT CODE TROUBLESHOOTING

ELECTRICAL SYSTEM COMPONENTS

CONTACTOR PANEL ASSEMBLY

DESCRIPTION/FEATURES

“EE” CONTACTOR PANEL

REMOVAL

INSTALLATION

CONTACTORS

TESTING

REMOVAL

INSTALLATION

SUPPRESSORS, DIODESAND RESISTORS

TESTING

FUSES

PROXIMITY SWITCHES

DESCRIPTION/FEATURES

OPERATION

TYPES

RELAYS

DESCRIPTION/FEATURES

24 INCH . .

150 INCH

212/272 INCH

ENABLE

HOUR METER

LATCH

COIL TESTING

CONTACT TESTING

REMOVAL

INSTALLATION

KEY SWITCH

REMOVAL

INSTALLATION

BATTERY DISCONNECT SWITCH

REMOVAL

INSTALLATION

HORN SWITCH

REMOVAL

INSTALLATION

SIDE GATE SWITCH

REMOVAL

INSTALLATION

ELECTRO-HYDRAULIC PROPORTIONAL VALVES

OPERATION . .

TESTING/REMOVAL/INSTALLATION

REMOVAL/INSTALLATION

CONTROL HANDLE

DESCRIPTION/FEATURES

OPERATION

DISASSEMBLY

ASSEMBLY

TRACTION AND HYDRAULIC POTENTIOMETERS

TESTING

INSTALLATID ADJUSTMENT

BATTERY CHARGE INDICATOR/HOURMETER

DESCRIPTION/FEATURES

TESTING

HOURMETER INPUT

BRAKE SWITCH INPUTS

REMOVAL

INSTALLATION

ADJUSTMENT (SET-UP)

VOLTAGE SELECTION

EV-100LX MOTOR CONTROLLER

EV-100LX DESCRIPTID OPERATION

THE SILICON CONTROLLED RECTIFIER (SCR)

A MOTOR CIRCUIT THAT OPERATES WITH PULSES

TRACTION CIRCUIT

THE SCR 1″OFF CIRCUIT

INDUCTION CURRENT FROM THE MOTOR

THE CONTROL CARD

PULSEMONITOR TRIP (PMT)

SRO CIRCUIT

CIRCUIT PROTECTION

CURRENT LIMIT

THERMAL PROTECTION

FILTER (SUPPRESSORS)

CONTROL CARDADJUSTMENTS (TRACTION CIRCUIT)

ACCELERATOR CONTROL

CONTROL CARD

SEQUENCE OFOPERATION

STATUS CODES

CONTROL CARD CONNECTIONS

HAND SET

CHECKS AND ADJUSTMENTS, CONTROL CARD

FUNCTION CODES

BENCH TESTS

TESTS-CONTROL CARD INSTALLED INA LIFT TRUCK

FUNCTION SETTINGS

GENERAL

CONNECT, DISCONNECT, AND CHECK THE HAND SET

CHECKAND ADJUST FUNCTIONS

ADJUSTING SPEED LIMIT 1

FUNCTION DESCRIPTIONS

TRACTION CONTROL CARD (LABEL LETTER TX)

TABLE FOR FUNCTION VALUE SETTINGS

TROUBLESHOOTING

MOTOR MAINTENANCE-GENERAL

BRUSHAND COMMUTATOR INSPECTION

NORMAL COMMUTATOR SURFACES

COMMUTATOR PROBLEMS

BRUSH REPLACEMENT-TRACTID HYDRAULIC MOTORS

REMOVAL

INSTALLATION

REMOVAL

INSTALLATION

REMOVAL

INSTALLATION

COMMUTATOR REPAIRS

TESTS

DAMAGED FIELDAND ARMATURE

SHORT-CIRCUIT INAN ARMATURE WINDING

SHORT-CIRCUIT IN THE ARMATURE

OPEN CIRCUIT INA FIELD COIL

SHORT-CIRCUIT INA FIELD COIL

SHORT-CIRCUIT BETWEEN FIELDAND MOTOR CASE

BRUSH HOLDER

WIRING DIAGRAMSAND SCHEMATICS

WIRING SCHEMATIC – EPS II ……. .

WIRING DIAGRAM- EPS II ……… . …….. .

OPTIONS DIAGRAM- EPS II

WIRING SCHEMATIC – WIRE GUIDANCE II

WIRING DIAGRAM- WIRE GUIDANCE II

OPTIONS DIAGRAM – WIRE GUIDANCE II

WIRING SCHEMATIC – EPS III

WIRING DIAGRAM – EPS III

OPTIONS DIAGRAM- EPS III

4 DRIVE UNIT

GENERAL

DESCRIPTION

REPAIR

REMOVAL

DISASSEMBLY

ASSEMBLY

BEVEL PINION SHAFT INSTALLATION

BEVEL GEAR INSTALLATION

CHECKS AND ADJUSTMENTS

BACKLASHAND TOOTH CONTACT PATTERN

AXLE SHAFT BEARING CLEARANCE

TRUNNION BEARING

INSTALLATION

TROUBLESHOOTING

5 BRAKE SYSTEM

GENERAL

DESCRIPTID OPERATION

BRAKE SWITCH

ELECTRIC BRAKE-REMOVAL AND DISASSEMBLY

ELECTRIC BRAKE-ASSEMBLYAND INSTALLATION

BRAKE SWITCH-REMOVE AND REPLACE

TROUBLESHOOTING

6 STEERING SYSTEM – EPS II AND EPS III

INTRODUCTION

GENERAL

DESCRIPTION

CHECKS AND ADJUSTMENTS

GENERAL

CHECKS

AUTOMATIC CHECKS

ECM CHECK

MANUAL CHECKS

CHECKING THE STEERING SYSTEM

FOR CORRECT OPERATION

CHECKING THE STEERING AT MASTHEIGHTS

CHECKING THE ECM POWER TRANSISTORS

CHECKING THE STEERING CONTACTOR

ADJUSTMENTS

GENERAL……

SETTING TRUCK CONFIGURATION

SETTING STEERING RESPONSE

ADJUSTING R4 TO THE OPERATIONAL MIDPOINT

ADJUSTING THE STEERING CHAIN CLEARANCE

CENTERING THE STEER TIRE

CENTERING THE MDUPOTENTIOMETER

ADJUSTING R3 FOR STRAIGHT TRAVEL

ADJUSTING THE TRAVEL SPEEDS

SLOW SPEED

REPAIR

GENERAL

STEERING GEARMOTOR

REPLACING THE GEARMOTOR ASSEMBLY

AND STEERING CHAIN

STEER WHEEL ASSEMBLY

REMOVAL AND DISASSEMBLY

ASSEMBLY AND INSTALLATION

REPLACE THE MDU POTENTIOMETER

REPLACE THE ECM

REPLACE THE COMPLETE MODULE

REPLACE THE LOGIC BOARD SET

REPLACE THE ECM POWER TRANSISTORS

REPLACE THE STEERING CONTACTOR

TROUBLESHOOTING

STEERING SYSTEM – EPS ID

GENERAL

DESCRIPTION

CHECKS AND ADJUSTMENTS

GENERAL

LED INDICATORS

DIPSWITCHES

CHECKS

CHECKING THE STEERING SYSTEM

FOR CORRECT OPERATION

CHECKING SLOW TRAVEL SPEED

CHECKING HIGH LIFT TRACTION SHUT-OFF

ADJUSTMENTS

TACHOMETER ADJUSTMENT

SENSITIVITYADJUSTMENT ….. .

FEEDBACK POTENTIOMETER ADJUSTMENT

SLOW TRAVEL ADJUSTMENT

STEERING CHAINADJUSTMENT

REPAIR

TACHOMETER REPLACEMENT

FEEDBACK POTENTIOMETER REPLACEMENT

ELECTRONIC CONTROL MODULE REPLACEMENT

STEER MOTOR ASSEMBLY AND STEERING CHAIN

REPLACEMENT

TYPICAL OPERATING VOLTAGES

TROUBLESHOOTING

7 STEERING SYSTEM – WIRE GUIDANCE II

INTRODUCTION

GENERAL

DESCRIPTION

OPERATION MODES

WIRE GUIDANCE

MANUAL STEERING

HOW TO OPERATE THE WIRE GUIDANCE SYSTEM

CHECKS AND ADJUSTMENTS

GENERAL

CHECKS

GENERAL

CHECKING FOR SHORT-CIRCUITS TO THE FRAME

CHECKS TO THE LIFT TRUCK

AUTOMATIC CHECKS

MANUAL CHECKS

CHECK 01- OPERATOR CONTROLS

CHECK 02 -STEERING INPUT VOLTAGE

CHECK 03 – MDUPOTENTIOMETER COARSEAMPLIFIER

CHECK 04 -MDU CENTERING

CHECK OS – DIRECTION INPUTS

CHECKS 06 THROUGH 09 – SENSOR LEVELS

CHECK 10 -STEERED END SENSOR BALANCE

CHECK 11- LOAD END SENSOR BALANCE

CHECK 13 – MEDIUM TRAVEL SPEED

CHECK 14 -SLOW TRAVEL SPEED

CHECKING THE OPERATION OF THE SHUT-OFF CIRCUIT

CHECKING THE STEERING AT MASTHEIGHTS

CHECKING THE ECM POWER TRANSISTORS

CHECKING THE STEERING CONTACTOR

ADJUSTMENTS . .

GENERAL.

ADJUSTING RT1 TO THE OPERATIONAL MIDPOINT

ADJUSTING THE STEERING CHAIN CLEARANCE

CENTERING THE STEER TIRE

CENTERING THE MDUPOTENTIOMETER

ADJUSTING RT2 FOR STRAIGHT TRAVEL

ADJUSTING THE TRAVEL SPEEDS

MEDIUM SPEED

SLOW SPEED

ADJUSTING SENSORS TO LIFT TRUCK CENTERLINE

REPAIR

GENERAL

STEERING GEARMOTOR

REPLACING THE GEARMOTOR ASSEMBLY

AND STEERING CHAIN

STEER WHEEL ASSEMBLY

REMOVAL AND DISASSEMBLY

ASSEMBLY AND INSTALLATION

REPLACE GUIDANCE SWITCH, INDICATOR AND ALARM

REPLACE THE MDUPOTENTIOMETER

REPLACE THE ECM

REPLACE THE COMPLETE MODULE

REPLACE THE LOGIC BOARD SET

REPLACE THE ECM POWER TRANSISTORS

REPLACE THE STEERING CONTACTOR

REPLACE THE SENSORS

TROUBLESHOOTING

8 HYDRAULIC SYSTEM

INTRODUCTION

DESCRIPTION

LIFT PUMP AND MOTOR

ELECTRO-HYDRAULIC CONTROL VALVE

MANUAL LOWERING

ACCUMULATOR

FLOW REGULATOR

FILTER

TANK

FREE LIFT CYLINDER

MAINLIFT CYLINDERS

VELOCITY FUSES

SPECIFICATIONS

LIFT PUMPAND MOTOR

ELECTRO-HYDRAULIC CONTROL VALVE

ADJUSTMENTS

REPAIRS

LIFT PUMPAND MOTOR

REMOVAL

SEAL REPLACEMENT

INSTALLATION

HYDRAULIC CONTROL VALVE

REMOVAL

INSTALLATION

DISASSEMBLY

ASSEMBLY

HYDRAULIC TANK

REMOVAL

DISASSEMBLY .

INSTALLATION

TROUBLESHOOTING

9 MAST

INTRODUCTION

DESCRIPTION

TRIPLEX MAST

OPERATOR’S COMPARTMENT

OPERATION-TRIPLEX MAST

SAFETY PROCEDURES WHEN WORKING NEAR THE MAST

CHECKS

CHECK MAST OPERATION

CHECK FOR LEAKS IN HYDRAULIC SYSTEM

REMOVEAIR FROM HYDRAULIC SYSTEM

CHECK LIFT CHAINS

CLEANING AND INSPECTION

ADJUSTMENTS

LOAD ROLLERS

ADJUST WEAR PLUGS

LUBRICATE CHAINS

ADJUST CHAINS

ADJUST FREE LIFT CHAIN

ADJUST MAIN LIFT CHAINS

ADJUST WEAR STRIPS

ADJUST SPRING WASHERS

MAINTENANCE

OPERATOR’S COMPARTMENT

REMOVAL

INSTALLATION

FORKS

REMOVAL

INSTALLATION

PALLET CLAMP

TRIPLEX MASTASSEMBLY

REMOVAL

CLEANING AND INSPECTION

INSTALLATION

INNER AND SECONDARY MASTASSEMBLIES

REMOVAL AND INSTALLATION

REPLACE HOSEAND CABLE SHEAVES

REPLACE HOSES

FREELIFT CYLINDER

REMOVAL

INSTALLATION

MAIN CYLINDERS

REMOVAL

INSTALLATION

DISASSEMBLY OFA LIFT CYLINDER

ASSEMBLY OFA LIFT CYLINDER

LOAD ROLLERSAND WEAR PLUGS

REMOVAL AND INSTALLATION

TROUBLESHOOTING-MAST

10 BATTERY AND CHARGING SYSTEM

GENERAL

SAFETY TIPS FOR HANDLING INDUSTRIAL TRUCK BATTERIES

BATTERY TROUBLESHOOTING

LEAD-ACID BATTERIES

SPECIFIC GRAVITY

CHEMICAL REACTION

HOW TO SELECT THE BATTERY

VOLTAGE OFA BATTERY

BATTERY RATINGS

KILOWATT HOURS

THE BATTERYAS A COUNTERWEIGHT

THE NEWBATTERY

BATTERY MAINTENANCE

MAINTENANCE RECORDS

CLEANING THE BATTERY

ADDING WATER

SPECIFIC GRAVITY

TEMPERATURE

CHARGING THE BATTERY

TYPES OF BATTERY CHARGES

DAILY CHARGE

EQUALIZING CHARGE

METHODS OF CHARGING

GRADUAL CHARGE

MODIFIED CONSTANT VOLTAGE

TWO-RATE CHARGE

TROUBLESHOOTING THE CHARGER

HOW TO KNOW WHEN THE BATTERY IS FULLY CHARGED.

BATTERY CHARGING AREA

EQUIPMENT NEEDED

PRECAUTIONS FOR BATTERIES IN STORAGE

11 USER SUPPORT INFORMATION

SERVICE PARTS ORDERING INSTRUCTIONS

TECHNICAL PUBLICATIONS

PARTS MANUALS

OPERATING MANUAL

OPERATOR TRAINING

SERVICE TRAINING COURSES

SERVICE TRAINING MATERIALS

12 ALPHABETICAL INDEX

=========

** Model Specification: Yale OS030BC, SS030BC Order Selector

** Language: English

** Total Pages: 304

** File Format: PDF

** Requirements: Adobe PDF Reader

** Compatible: All Versions of Windows & Mac, Linux OS, Iphone, Ipad, Android etc…

=========

This QUALITY manual is 100 percents COMPLETE and INTACT,

no MISSING/CORRUPT pages/sections to freak you out! It also is Bookmarked and SEARCHABLE to make what you need easy to find. Complete download comes in PDF format which can work under all PC based Windows operating system and Mac also. It saves to your hard-drive and can be burned to CD-ROM. It can be viewed on any computer, as well as zoomed and printed.